Professional Design Multi Inserts Chair Mold - Dustbin Mould – Aojie Mould

Professional Design Multi Inserts Chair Mold - Dustbin Mould – Aojie Mould Detail:

Aojie MOULD

Aojie has more than ten years experience in automotive molds. We cooperate with large auto parts manufacturer from European and North American. Our specialty tooling includes molds for Bumpers, Door Panels, interior and exterior parts and lamp molds.

Supplier:

Texture: Mold-Tech Meantime, we have own mold for testing texture to assurance accuracy.

Hotrunner: Synventive YUDO Moldmaster Husky.

JSL optimization the mold flow system with our hot runner supplier and they have global guarantee. We also have Moldflow analysis capacity.

Steel:Many kinds of imported steel,like Buderus,Assab,FINKL.

Customer: Germany Audi ; Germany Mercedes-Benz ; Germany BMW ; Volkswagen; HYUNDAI Korea ; American GE .

Advantages of JSL

· Patient communication. During the design, we know customer’s all side requests through deeper communication.

· Strict quality control system and professional experience.

· Strive for perfection. After the mould trial,we will inspect the sample with CMM.Then modify the mold according to customer’s request till satisfied with our mold.

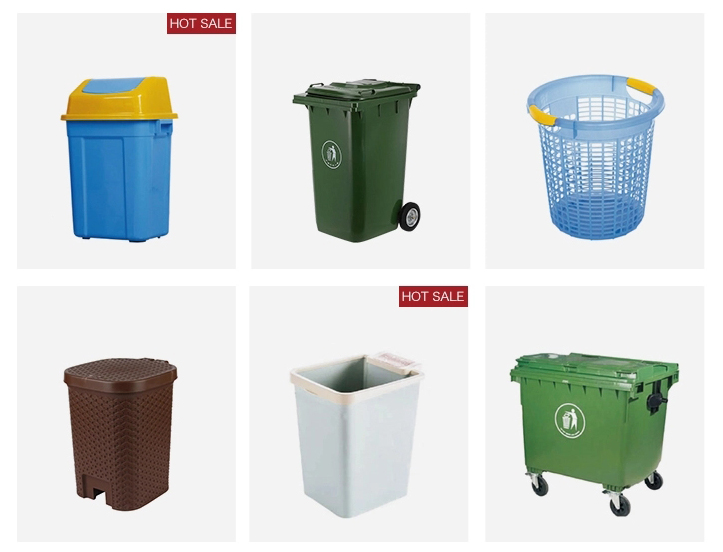

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and growth, we're going to build a prosperous future together with your esteemed firm for Professional Design Multi Inserts Chair Mold - Dustbin Mould – Aojie Mould , The product will supply to all over the world, such as: Thailand, Haiti, Libya, Since its foundation , the company keeps living up to the belief of "honest selling , best quality , people-orientation and benefits to customers. " We are doing everything to offer our customers with best services and best products . We promise that we'll be responsible all the way to the end once our services begin.

Q: What services do you provide?

A: We manufacture plastic injection molds and produce plastic injection parts for sampling and bulk production.We also provide mold design services.

Q: How can I contact you?

A: You can send us an inquiry via email, WhatsApp, Skype or Wechat. We will reply to you within 24 hours.

Q: How can I get a quotation?

A:After receving your RFQ, we will reply to you within 2 hours. In your RFQ, please provide the following information and data in order for us to send you competitive pricing based on your requirements.a) 2D part drawings in PDF or JPG format & 3D part drawings in UG, PRO/E, SOLIDWORKS, CATIA, CAD, STP, X_T, IGS, PRT, DWG, or DXFb) Resin information (Datasheet)c) Annual quantity requirement for parts

Q: What shall we do if we don’t have part drawings?

A: You can send us your plastic part samples or photos with dimensions and we could provide you our technical solutions. We will create .

Q: Can we get some samples before mass production?

A: Yes, we will send you samples for confirmation before start of mass production.

Q: Due to time difference with China and overseas, how can I get information about my order progress?

A: Every week we send weekly production progress report with digital pictures and videos that shows the production progress.

Q: What is your leadtime?

A: Our standard leadtime for mold production is 4 weeks.For plastic parts is 15-20 days depending on the quantity.

Q: What is your payment term?

A: 50% as payment deposit, 50% balance will be paid before shipping. For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred

Q: How can I guarantee our quality?

A: During mold making, we do material and part inspection. During part production, we do 100% full quality inspection

before packaging and reject every parts that is not according to our quality standard or the quality approved by our client.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.