Professional China Auto Window Trim Molding - Bumper mould – Aojie Mould

Professional China Auto Window Trim Molding - Bumper mould – Aojie Mould Detail:

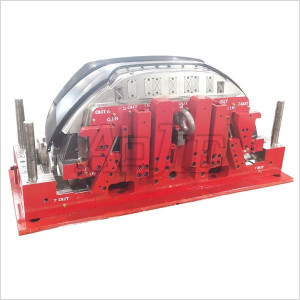

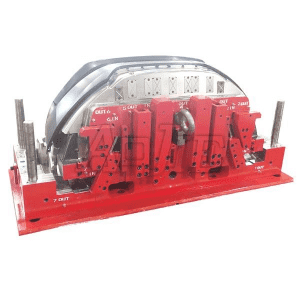

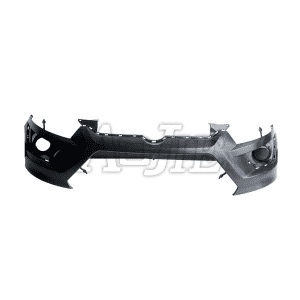

Aojie Mould has been supplying the front auto bumper mould, back auto bumper mould and auto grill mould to different auto makers. With the improving of customer’s request for surface of car bumper mold, the structure of outer departing surface can’t meet the need of market. So Aojie Mould have been accumulating the experience and importing the advanced technology in auto mould.

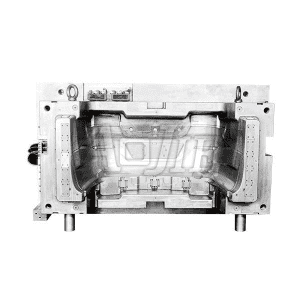

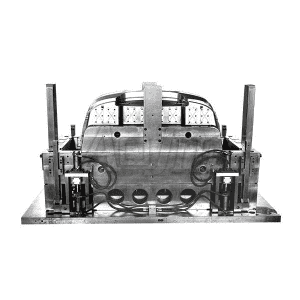

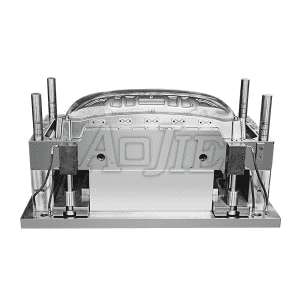

1.Structure of inner departing surface:

Hafo can master the structure and set the departing line on the non exterior surface to be ejected, so it will avoid small step on the surface of auto bumper and avoid the issue of cutting flash. At finally, it helps to realize the smooth surface of auto bumper.

2.Location of injection gate:

The reasonable arrangement of injection gate can reduce the pressure difference of cavity, it directly affects the quality of the bumper products.

3.Pick-up position of product:

Since the injection molding part is left in the cavity and core, reasonable product ejection mechanism is very important.

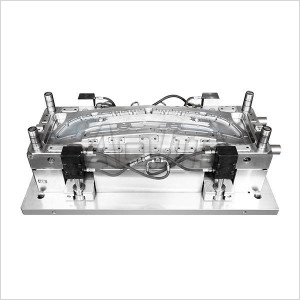

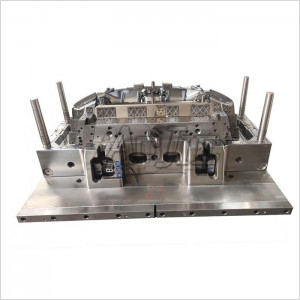

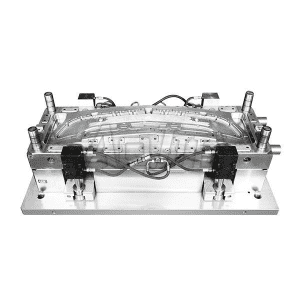

Auto Bumper Mould

Item name: Auto Bumper Mould

Material: PP/ABS

Size #

OEM/ODM Service #

Lead time: 55days after deposit

Packing Details: wooden box

Payment & Shipping Terms Payment terms :T/T(30% deposit, 70% before shipment)

Shipping Port: zhejiang

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for Professional China Auto Window Trim Molding - Bumper mould – Aojie Mould , The product will supply to all over the world, such as: Juventus, Malaysia, Iran, We aspire to meet the demands of our customers globally. Our range of merchandise and services is continuously expanding to meet customers' requirements. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Q: What services do you provide?

A: We manufacture plastic injection molds and produce plastic injection parts for sampling and bulk production.We also provide mold design services.

Q: How can I contact you?

A: You can send us an inquiry via email, WhatsApp, Skype or Wechat. We will reply to you within 24 hours.

Q: How can I get a quotation?

A:After receving your RFQ, we will reply to you within 2 hours. In your RFQ, please provide the following information and data in order for us to send you competitive pricing based on your requirements.a) 2D part drawings in PDF or JPG format & 3D part drawings in UG, PRO/E, SOLIDWORKS, CATIA, CAD, STP, X_T, IGS, PRT, DWG, or DXFb) Resin information (Datasheet)c) Annual quantity requirement for parts

Q: What shall we do if we don’t have part drawings?

A: You can send us your plastic part samples or photos with dimensions and we could provide you our technical solutions. We will create .

Q: Can we get some samples before mass production?

A: Yes, we will send you samples for confirmation before start of mass production.

Q: Due to time difference with China and overseas, how can I get information about my order progress?

A: Every week we send weekly production progress report with digital pictures and videos that shows the production progress.

Q: What is your leadtime?

A: Our standard leadtime for mold production is 4 weeks.For plastic parts is 15-20 days depending on the quantity.

Q: What is your payment term?

A: 50% as payment deposit, 50% balance will be paid before shipping. For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred

Q: How can I guarantee our quality?

A: During mold making, we do material and part inspection. During part production, we do 100% full quality inspection

before packaging and reject every parts that is not according to our quality standard or the quality approved by our client.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!