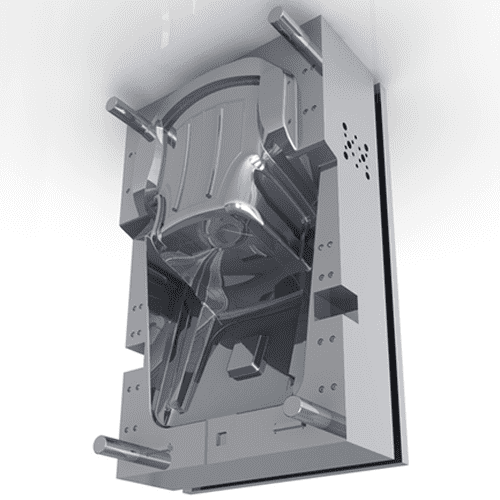

Personlized Products Hdpe Outdoor Plastic Dustbin - Children Dining Chair Mold – Aojie Mould

Personlized Products Hdpe Outdoor Plastic Dustbin - Children Dining Chair Mold – Aojie Mould Detail:

| Place of Origin | Zhejiang, China (Mainland) |

| Brand Name | Aojie Mould |

| Shaping Mode | Plastic Injection Mould |

| Product Material | Plastic |

| CNC Machining Tolerance | 0.003to 0.005mm |

| Core & Cavity Material | P20, 718,2316… |

| Runner shot | Cold or Hot runner |

| Mold life | 300.000 shots-500.000 shots. |

| Cycle time | 30-50s |

| Delivery time | 45-60 days |

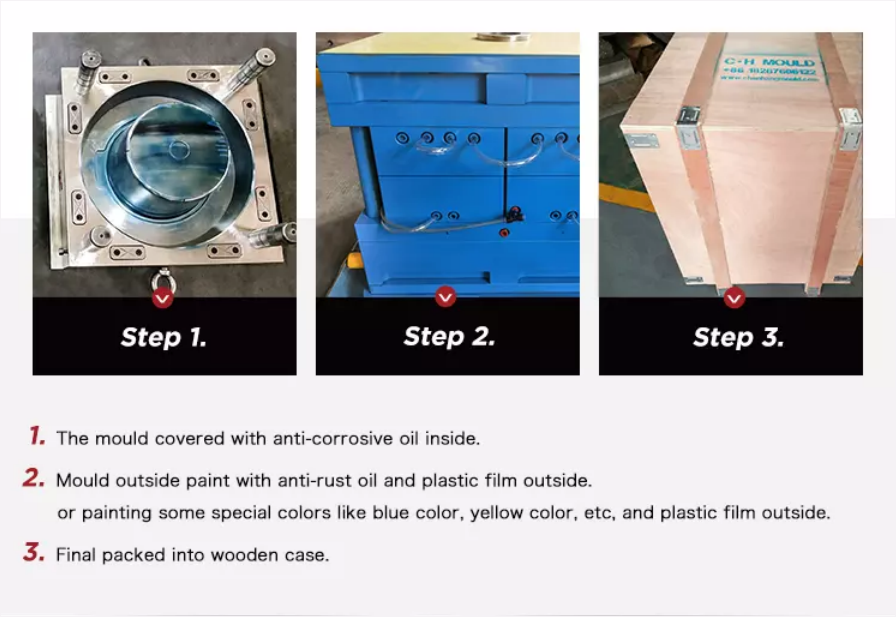

| Package | STANDARD Wooden case |

| Delivery | By sea |

| Different size and shape according to your requirements | |

Product detail pictures:

Related Product Guide:

Now we have superior devices. Our solutions are exported to your USA, the UK and so on, enjoying a superb name between customers for Personlized Products Hdpe Outdoor Plastic Dustbin - Children Dining Chair Mold – Aojie Mould , The product will supply to all over the world, such as: Sydney, Mauritius, South Korea, With many years good service and development, we have a qualified international trade sales team. Our goods have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

Q: What services do you provide?

A: We manufacture plastic injection molds and produce plastic injection parts for sampling and bulk production.We also provide mold design services.

Q: How can I contact you?

A: You can send us an inquiry via email, WhatsApp, Skype or Wechat. We will reply to you within 24 hours.

Q: How can I get a quotation?

A:After receving your RFQ, we will reply to you within 2 hours. In your RFQ, please provide the following information and data in order for us to send you competitive pricing based on your requirements.a) 2D part drawings in PDF or JPG format & 3D part drawings in UG, PRO/E, SOLIDWORKS, CATIA, CAD, STP, X_T, IGS, PRT, DWG, or DXFb) Resin information (Datasheet)c) Annual quantity requirement for parts

Q: What shall we do if we don’t have part drawings?

A: You can send us your plastic part samples or photos with dimensions and we could provide you our technical solutions. We will create .

Q: Can we get some samples before mass production?

A: Yes, we will send you samples for confirmation before start of mass production.

Q: Due to time difference with China and overseas, how can I get information about my order progress?

A: Every week we send weekly production progress report with digital pictures and videos that shows the production progress.

Q: What is your leadtime?

A: Our standard leadtime for mold production is 4 weeks.For plastic parts is 15-20 days depending on the quantity.

Q: What is your payment term?

A: 50% as payment deposit, 50% balance will be paid before shipping. For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred

Q: How can I guarantee our quality?

A: During mold making, we do material and part inspection. During part production, we do 100% full quality inspection

before packaging and reject every parts that is not according to our quality standard or the quality approved by our client.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.