1. The wall thickness should be as uniform as possible, and the draft angle should be large.

2. The transition part should be gradual and smooth.

3. Gate. The runner should be as wide as possible, thick and short, and the gate position should be set according to shorten the condensation process, and if necessary, a cold well should be added.

4. The surface of the mold should be bright, with low roughness (preferably lower than 0.8)

5. Exhaust holes and grooves must be met to discharge air and gas in the melt in a timely manner

6. Except for PET, the wall thickness should not be too thin, generally not less than 1mm.

Frequent defects in plastic parts?

Lack of glue→cloak→bubble→shrinkage→weld mark→black dots→stripe→lifting→delamination→peeling

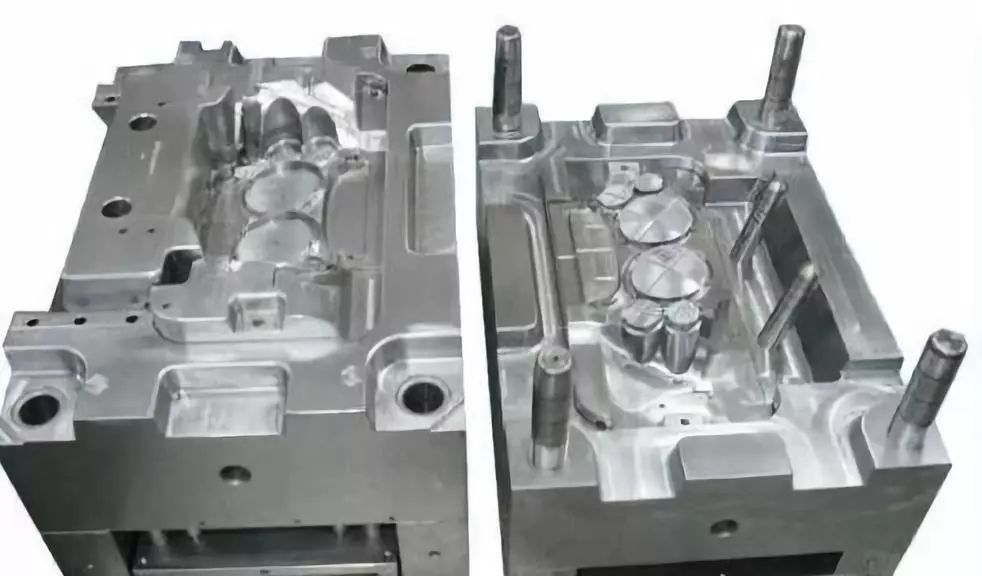

What structure does the mold base have?

Panel → A board → B board → square iron → guide post → thimble plate → thimble fixing plate → bottom plate

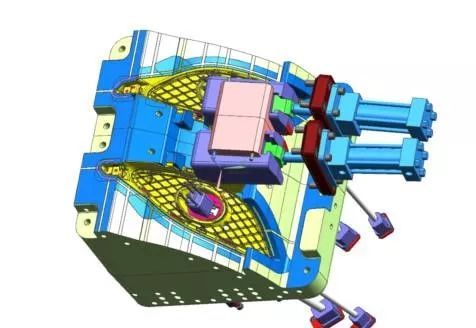

What are the basic forms of the parting surface?

Straight→Skewed→Curved→Straight→Curved

What are the mold processing machinery and equipment?

Computer Gong→Lathe→Milling Machine→Grinding Machine→Drilling Machine

What is the default accuracy of pro/e? What is the default accuracy of UG?

The default accuracy of pro/e is: 0.0012MM, and the default accuracy of UG is: 0.0254MM

What is bump and penetration?

The mating surface of the male and female molds parallel to the PL surface is called the piercing surface, and the mating surface of the male and female molds that is not parallel to the PL surface is called the inserting surface.

Frequent defects in plastic parts?

Lack of glue → cloak → bubbles → shrinkage → weld marks → black dots → stripes → warping → layering → peeling commonly used plastic mold steel?

45# S50c 718 738 718H

NAK80 NAK55 S136 S136H SKD61

Which type of material is used for high mirror polishing?

Commonly used high-hardness heat-treated steel, such as: SKD61, 8407, S136

Post time: Dec-01-2021