Do you still remember the knowledge about the production of automotive interior molds that I shared with you in the last article? Next, this article will continue to bring you how to make automotive interior molds and the precautions for making them.

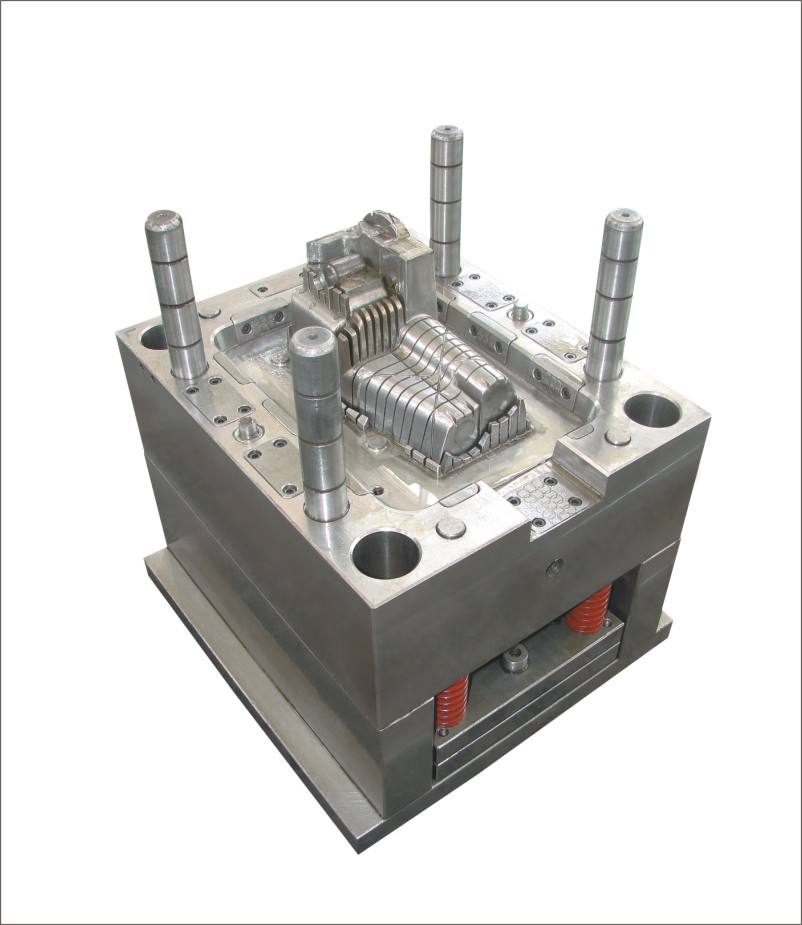

1. Mold structure

Taking into account the particularity of product molding and the characteristics of mold materials, the structure of the automotive interior molds we manufactu ations. Staggered support ribs, the upper and lower bottom plates of the mold are made of channel steel or I-beam, and the entire mold is made of aluminum alloy castings.

2. The extension design of the forming surface

Since the skeleton of the interior parts product needs to be heated and softened before molding, resulting in a drawing deformation, and then it is attached to the fabric, it is necessary to ensure that the outside of the product remains relatively static under the action of a certain tension during the molding process. At the same time, considering the possibility of extending the final product outline according to the actual loading situation, in the mold design, referring to the practice of metal drawing die, the molding surface of the product is extended by 15mm according to the original trend, which is not only the product molding process needs , and can strengthen the strength of the periphery of the automotive interior mold. Then, according to the product surface modeling, use the thickening operation of the UGII software to complete the overall design and modeling of a single mold. Similarly, by offsetting the wall thickness of the interior product, the three-dimensional modeling of another mold can be obtained.

3. Design of cooling water pipes

During the molding process of interior trim products, the skeleton material is heated and softened first, and the temperature needs to reach 150-200 degrees Celsius to make it plastic and easy to draw. When the softened material is formed and bonded with the fabric, it needs to be cooled and shaped in time to prevent the product from being deformed after being taken out of the automotive interior mold, so it is necessary to quickly cool the automotive interior mold. The cooling mold adopts the water cooling method, that is, the cooling water pipe is laid in the automobile interior mold. Due to the special requirements of product material cooling, it is necessary to arrange the cooling water pipes evenly, preferably keeping the same distance from the molding surface of the mold.

I believe that everyone has some understanding of how to make automotive interior molds. If you have any questions, please contact Aojie Mold Company, we will serve you wholeheartedly!

Post time: Feb-15-2022