The turnover box can be used for both turnover and finished product shipment packaging, and is lightweight, durable, and stackable. Various specifications and sizes can be customized according to user needs, aluminum alloy edging, can be covered, dust-proof, beautiful appearance. It can be used in hardware, electronics, mechanical spare parts, refrigeration, storage, transportation and other industries. Generally, the hollow board turnover box is designed and manufactured according to the size provided by the customer, so that the most reasonable loading can be achieved, and multiple boxes can be overlapped, making effective use of the workshop space, increasing the storage capacity of parts, and saving production costs. In logistics management, more and more enterprises are used Today, the turnover box helps to complete the generalization and integrated management of logistics containers, and is a must for production and distribution enterprises to carry out modern logistics management.

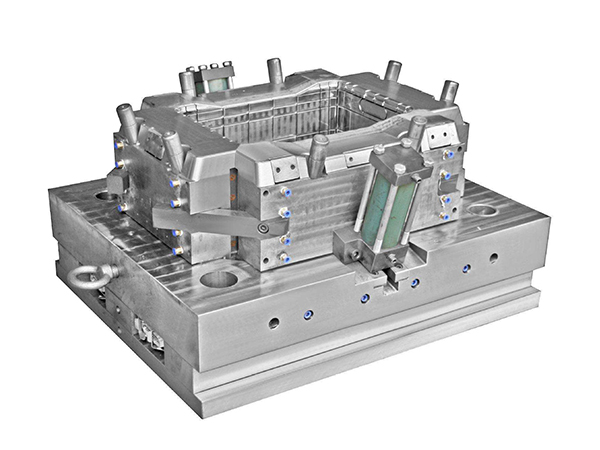

The turnover box mold is one of the indispensable tools in the production and processing of the turnover box. Now the turnover box molds are mostly punches on the bottom and concave molds on the top. For the newly formed turnover box, the unloading pressure is large and it is easy to damage the newly formed turnover box, so how do we solve these problems?

Technical scheme: The turnover box mold includes a fixed template, a movable template is arranged above the fixed template, and the fixed template and the movable template are connected by electric telescopic rods, the upper surface of the fixed template is provided with a concave mold, the concave mold An injection port is opened on the front surface of the die, and an injection nozzle is provided on the upper surface of the die. One end of the injection port is communicated with the external high-pressure grouting gun, and the other end of the injection port is communicated with the injection nozzle through a pipeline. , a plastic mesh frame is installed inside the concave mold, a discharge plate is installed below the plastic mesh frame, and a discharge cavity is opened below the concave mold at the corresponding position of the discharge plate. An unloading telescopic rod is installed inside the material cavity, a punch is arranged at a position corresponding to the lower surface of the movable platen and the female mould, and a material guide groove is provided around the punch.

If you want to know more, please contact us, AJ Mould will serve you wholeheartedly.

Post time: Feb-23-2022