Low price for Plastic Big Board Mould - Auto Crate Mould – Aojie Mould

Low price for Plastic Big Board Mould - Auto Crate Mould – Aojie Mould Detail:

China Auto Parts Production Base” and “China Auto and Motor Parts Base”. Aojie Mould are a responsible plastic mould manufacturer, which is specialized in developing, designing, manufacturing and processing various kinds of large or Auto Crate Mould medium size plastic moulds for both international and national .

1.Product Introduction:

We are not just a simple injection plastic manufacturer,more focus on customized service and project solution, insist on customer first. Therefore, we have this ability to work with you from idea to product finish, no matter how simple or complicated, you just need to trust us and give your initial advice, we will give you one-stop solution.

2.Production feature and application:

a. Our top priority is honesty and sincere, we would like to cooperate with client as a friend on mutual benefit rather than simply do business.

b. We will keep secret of your new idea, If necessary, we can sign “confidentiality agreement” with you

c. With 10years experience of customized service, we know very well customer’s demand, it’s very easy to communicate with us, just tell us what you need.

d. Skilled 3d design and technical team in Solidworks, CAD, UG and other 3d drawing software.

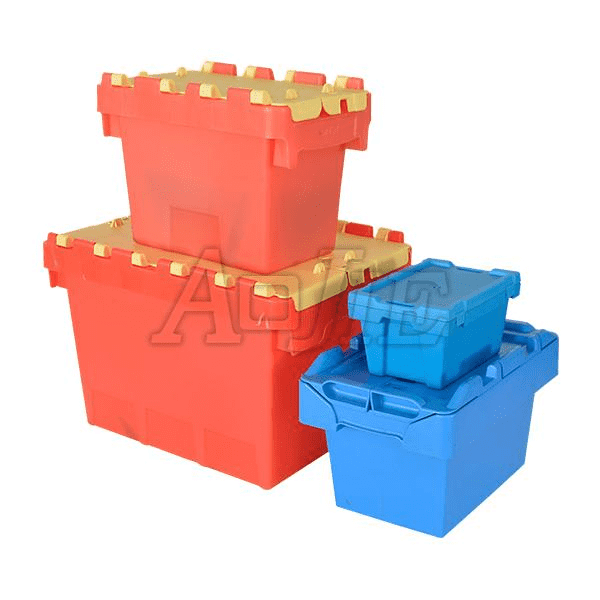

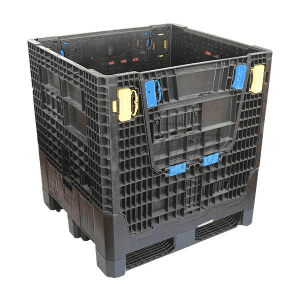

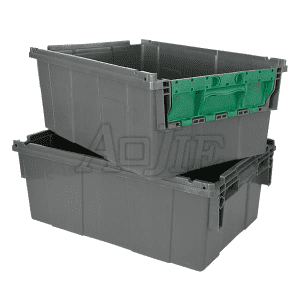

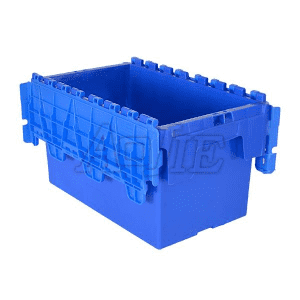

Product detail pictures:

Related Product Guide:

We stick to our enterprise spirit of "Quality, Performance, Innovation and Integrity". We purpose to create a lot more price for our prospects with our rich resources, innovative machinery, experienced workers and great products and services for Low price for Plastic Big Board Mould - Auto Crate Mould – Aojie Mould , The product will supply to all over the world, such as: Iraq, Mauritania, Bulgaria, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

Q: What services do you provide?

A: We manufacture plastic injection molds and produce plastic injection parts for sampling and bulk production.We also provide mold design services.

Q: How can I contact you?

A: You can send us an inquiry via email, WhatsApp, Skype or Wechat. We will reply to you within 24 hours.

Q: How can I get a quotation?

A:After receving your RFQ, we will reply to you within 2 hours. In your RFQ, please provide the following information and data in order for us to send you competitive pricing based on your requirements.a) 2D part drawings in PDF or JPG format & 3D part drawings in UG, PRO/E, SOLIDWORKS, CATIA, CAD, STP, X_T, IGS, PRT, DWG, or DXFb) Resin information (Datasheet)c) Annual quantity requirement for parts

Q: What shall we do if we don’t have part drawings?

A: You can send us your plastic part samples or photos with dimensions and we could provide you our technical solutions. We will create .

Q: Can we get some samples before mass production?

A: Yes, we will send you samples for confirmation before start of mass production.

Q: Due to time difference with China and overseas, how can I get information about my order progress?

A: Every week we send weekly production progress report with digital pictures and videos that shows the production progress.

Q: What is your leadtime?

A: Our standard leadtime for mold production is 4 weeks.For plastic parts is 15-20 days depending on the quantity.

Q: What is your payment term?

A: 50% as payment deposit, 50% balance will be paid before shipping. For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred

Q: How can I guarantee our quality?

A: During mold making, we do material and part inspection. During part production, we do 100% full quality inspection

before packaging and reject every parts that is not according to our quality standard or the quality approved by our client.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.