Factory directly Plastic Rear Bumper Mould - Beer Crate Mould – Aojie Mould

Factory directly Plastic Rear Bumper Mould - Beer Crate Mould – Aojie Mould Detail:

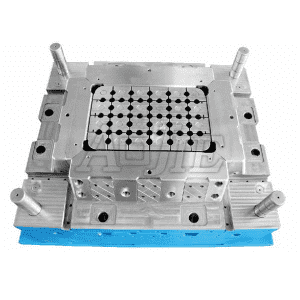

Because the structure of beer Crate is more complicated, we adopts beryllium copper insert to shorten the cooling time and pulling structure is used during the injection. Since the beer box is cosmetic part, the deformation of the beer crate plastic parts is required to be small to achieve a convenient mold assembly. There should be no gates or ejection pin trail on the surface of the plastic part.

Beer crate mold walls require core pulling and use Ha barking structure in the Four sides. In the production, sometimes the haw wedge is too tight, as well as the beer crate remain in the unclassified part line and difficult to demoulding. To solves this problem, we made the Ha barking with the pulling hook move out at the same time.

Item name: Beer Crate Mould

Material: PP/PE

Size #

OEM/ODM Service #

Lead time: 25-55days after deposit

Packing Details: wooden box

Payment & Shipping Terms Payment terms :T/T(30% deposit, 70% before shipment)

Shipping Port: guangzhou

Product detail pictures:

Related Product Guide:

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we're devoted to supplying the top benefit for our customers for Factory directly Plastic Rear Bumper Mould - Beer Crate Mould – Aojie Mould , The product will supply to all over the world, such as: Lithuania, Puerto Rico, Melbourne, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

Q: What services do you provide?

A: We manufacture plastic injection molds and produce plastic injection parts for sampling and bulk production.We also provide mold design services.

Q: How can I contact you?

A: You can send us an inquiry via email, WhatsApp, Skype or Wechat. We will reply to you within 24 hours.

Q: How can I get a quotation?

A:After receving your RFQ, we will reply to you within 2 hours. In your RFQ, please provide the following information and data in order for us to send you competitive pricing based on your requirements.a) 2D part drawings in PDF or JPG format & 3D part drawings in UG, PRO/E, SOLIDWORKS, CATIA, CAD, STP, X_T, IGS, PRT, DWG, or DXFb) Resin information (Datasheet)c) Annual quantity requirement for parts

Q: What shall we do if we don’t have part drawings?

A: You can send us your plastic part samples or photos with dimensions and we could provide you our technical solutions. We will create .

Q: Can we get some samples before mass production?

A: Yes, we will send you samples for confirmation before start of mass production.

Q: Due to time difference with China and overseas, how can I get information about my order progress?

A: Every week we send weekly production progress report with digital pictures and videos that shows the production progress.

Q: What is your leadtime?

A: Our standard leadtime for mold production is 4 weeks.For plastic parts is 15-20 days depending on the quantity.

Q: What is your payment term?

A: 50% as payment deposit, 50% balance will be paid before shipping. For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred

Q: How can I guarantee our quality?

A: During mold making, we do material and part inspection. During part production, we do 100% full quality inspection

before packaging and reject every parts that is not according to our quality standard or the quality approved by our client.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.