Factory Cheap Hot Plastic Motorcycle Helmet Mold - Motorcycle Scooter Mould – Aojie Mould

Factory Cheap Hot Plastic Motorcycle Helmet Mold - Motorcycle Scooter Mould – Aojie Mould Detail:

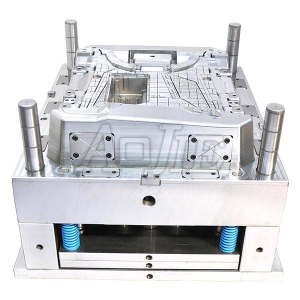

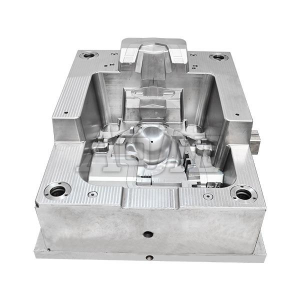

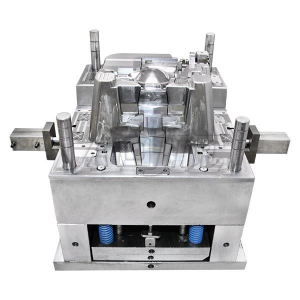

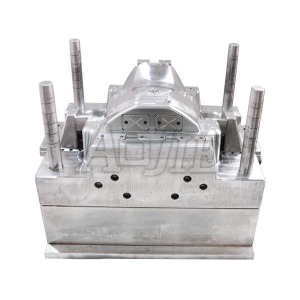

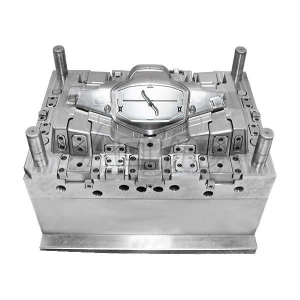

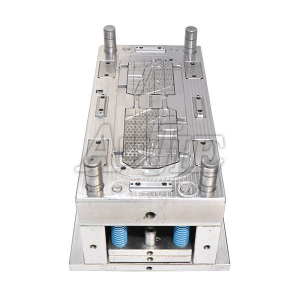

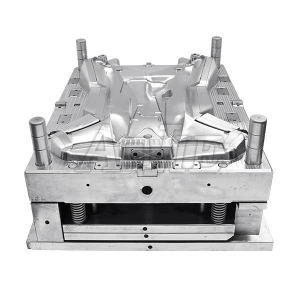

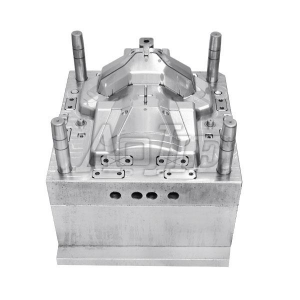

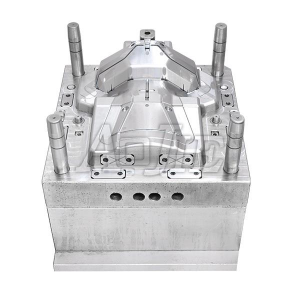

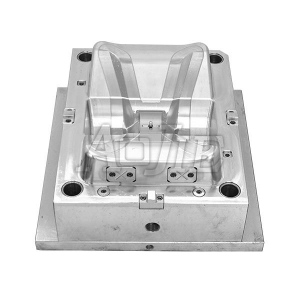

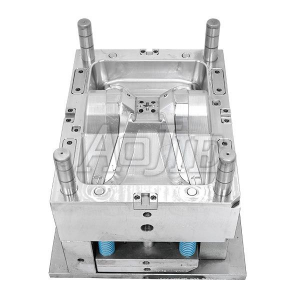

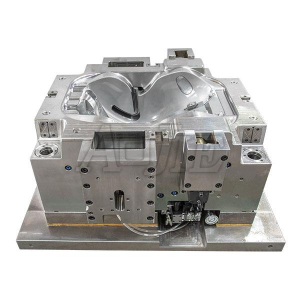

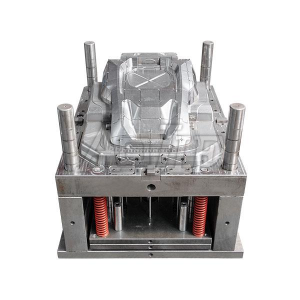

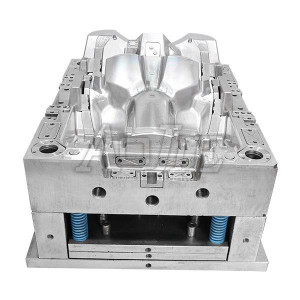

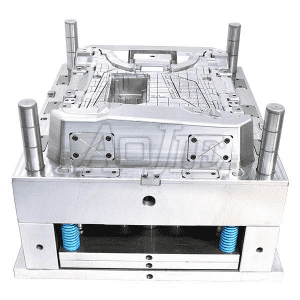

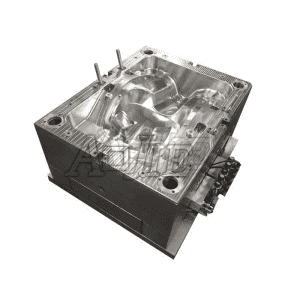

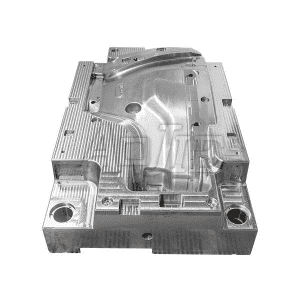

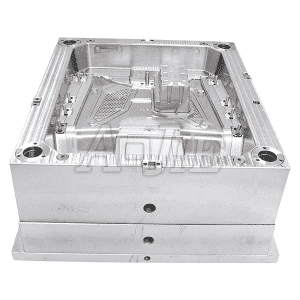

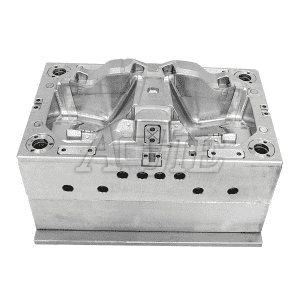

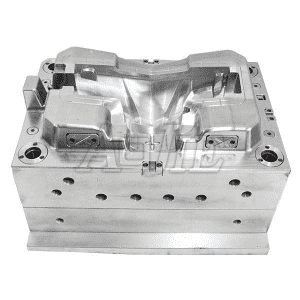

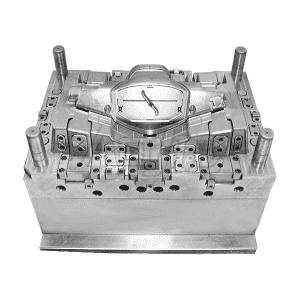

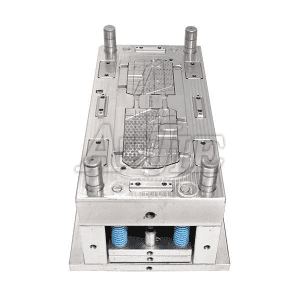

Motorcycle Scooter Mould

Product Name Taizhou Experienced OEM Motorbike rear cowl Plastic Mould

Product material abs

Core& Cavity Steel 718/2738

Steel hardness: HRC34-38

Mould Standard DME/LKM/HASCO

Cavity Number 1+1

Injection System side Gate

Ejector System ejector pin

Cycle Time 50seconds/shot

Tooling lead time 50days

Mould life 500, 000 times

Quality assurance ISO9001

Our Advantage

1. High quality

2. Reasonable price

3. On time delivery

4. Good After-sale service

5. Strict quality control

6. All the mould are automotic.

Offer you In-time response on letters, telephone calls or fax

In-time supply the quotation and mould designs

In-time communication on the technical points

In-time sending pictures for the mould machining progress and mould finishing schedule

In-time mould test and sample delivery

In-time mould delivery

Product detail pictures:

Related Product Guide:

We retain improving upon and perfecting our items and repair. At the same time, we perform actively to do research and progress for Factory Cheap Hot Plastic Motorcycle Helmet Mold - Motorcycle Scooter Mould – Aojie Mould , The product will supply to all over the world, such as: Bahamas, Estonia, Uganda, we have all day online sales to make sure the pre-sale and after-sale service in time. With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

Q: What services do you provide?

A: We manufacture plastic injection molds and produce plastic injection parts for sampling and bulk production.We also provide mold design services.

Q: How can I contact you?

A: You can send us an inquiry via email, WhatsApp, Skype or Wechat. We will reply to you within 24 hours.

Q: How can I get a quotation?

A:After receving your RFQ, we will reply to you within 2 hours. In your RFQ, please provide the following information and data in order for us to send you competitive pricing based on your requirements.a) 2D part drawings in PDF or JPG format & 3D part drawings in UG, PRO/E, SOLIDWORKS, CATIA, CAD, STP, X_T, IGS, PRT, DWG, or DXFb) Resin information (Datasheet)c) Annual quantity requirement for parts

Q: What shall we do if we don’t have part drawings?

A: You can send us your plastic part samples or photos with dimensions and we could provide you our technical solutions. We will create .

Q: Can we get some samples before mass production?

A: Yes, we will send you samples for confirmation before start of mass production.

Q: Due to time difference with China and overseas, how can I get information about my order progress?

A: Every week we send weekly production progress report with digital pictures and videos that shows the production progress.

Q: What is your leadtime?

A: Our standard leadtime for mold production is 4 weeks.For plastic parts is 15-20 days depending on the quantity.

Q: What is your payment term?

A: 50% as payment deposit, 50% balance will be paid before shipping. For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred

Q: How can I guarantee our quality?

A: During mold making, we do material and part inspection. During part production, we do 100% full quality inspection

before packaging and reject every parts that is not according to our quality standard or the quality approved by our client.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!