Excellent quality Plastic Children’s Table Mould - Plastic Injection Bathtub Mould – Aojie Mould

Excellent quality Plastic Children’s Table Mould - Plastic Injection Bathtub Mould – Aojie Mould Detail:

| Place of Origin | Zhejiang, China (Mainland) |

| Brand Name | Aojie Mould |

| Shaping Mode | Plastic Injection Mould |

| Product Material | Plastic |

| CNC Machining Tolerance | 0.003to 0.005mm |

| Core & Cavity Material | P20, 718,2316… |

| Runner shot | Cold or Hot runner |

| Mold life | 300.000 shots-500.000 shots. |

| Cycle time | 30-50s |

| Delivery time | 45-60 days |

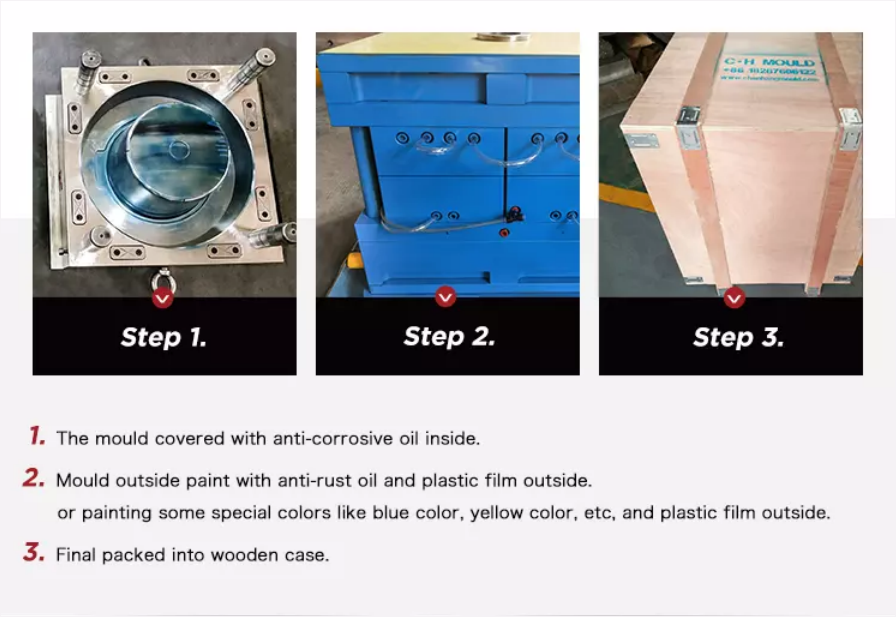

| Package | STANDARD Wooden case |

| Delivery | By sea |

| Different size and shape according to your requirements | |

Product detail pictures:

Related Product Guide:

To be able to ideal satisfy client's requirements, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Price tag, Fast Service" for Excellent quality Plastic Children’s Table Mould - Plastic Injection Bathtub Mould – Aojie Mould , The product will supply to all over the world, such as: Uzbekistan, Islamabad, Japan, We are introduced as a one of the growing manufacture supplier and export of our products. We have a team of dedicated trained professional who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

Q: What services do you provide?

A: We manufacture plastic injection molds and produce plastic injection parts for sampling and bulk production.We also provide mold design services.

Q: How can I contact you?

A: You can send us an inquiry via email, WhatsApp, Skype or Wechat. We will reply to you within 24 hours.

Q: How can I get a quotation?

A:After receving your RFQ, we will reply to you within 2 hours. In your RFQ, please provide the following information and data in order for us to send you competitive pricing based on your requirements.a) 2D part drawings in PDF or JPG format & 3D part drawings in UG, PRO/E, SOLIDWORKS, CATIA, CAD, STP, X_T, IGS, PRT, DWG, or DXFb) Resin information (Datasheet)c) Annual quantity requirement for parts

Q: What shall we do if we don’t have part drawings?

A: You can send us your plastic part samples or photos with dimensions and we could provide you our technical solutions. We will create .

Q: Can we get some samples before mass production?

A: Yes, we will send you samples for confirmation before start of mass production.

Q: Due to time difference with China and overseas, how can I get information about my order progress?

A: Every week we send weekly production progress report with digital pictures and videos that shows the production progress.

Q: What is your leadtime?

A: Our standard leadtime for mold production is 4 weeks.For plastic parts is 15-20 days depending on the quantity.

Q: What is your payment term?

A: 50% as payment deposit, 50% balance will be paid before shipping. For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred

Q: How can I guarantee our quality?

A: During mold making, we do material and part inspection. During part production, we do 100% full quality inspection

before packaging and reject every parts that is not according to our quality standard or the quality approved by our client.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.