Best quality Aluminum Die Casting Automotive Part - Automobile Grille Plastic Injection Mould – Aojie Mould

Best quality Aluminum Die Casting Automotive Part - Automobile Grille Plastic Injection Mould – Aojie Mould Detail:

Why customers choose Aojie Mould?

1. Mould design experience for more than 20 years

2. The strength of production capacity, can hold 400 sets yearly and on time delivery

3. High quality with strict quality control

4. Better communication skills and good service with customers, the schedule is made Weekly reports with detailed photos, sent to customers for monitoring

5. Not only supply plastic moulds, but also supply rapid prototypes and plastic parts injection

6. Provide low-volume production to ensure mould quality before shipment

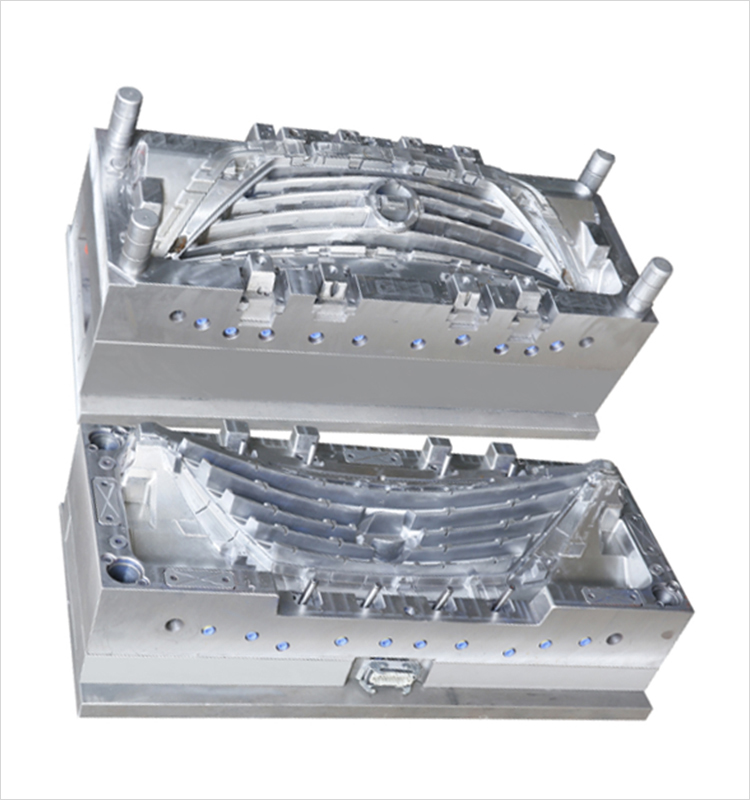

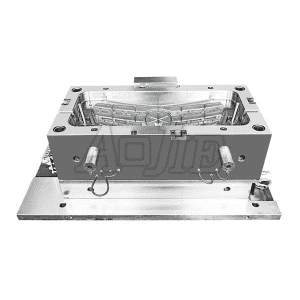

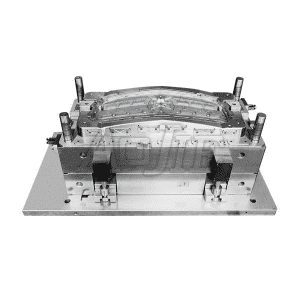

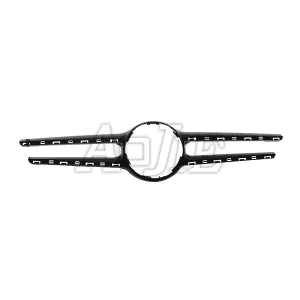

Car Parts Front Grille Grill Injection Mould, The main machining features is Wire Discharge Machining works for electrodes manufacturing, surface finishing can be the electroplating treatment, we help our customer to support part design and mould design pre-review before we start mould design, mould standard components can be DME or DME equivalent, HASCO, or HASCO equivalent, we also supply you a set of easy- damaged mould components when we ship the mould to your factory. Our mould warranty is two years, if you have any technical requirements during two years, we may give you quick response and some of parts are free of charge depends on production.

Product detail pictures:

Related Product Guide:

It truly is a great way to improve our merchandise and repair. Our mission should be to create imaginative products to prospects with a excellent knowledge for Best quality Aluminum Die Casting Automotive Part - Automobile Grille Plastic Injection Mould – Aojie Mould , The product will supply to all over the world, such as: Birmingham, Albania, Benin, Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

Q: What services do you provide?

A: We manufacture plastic injection molds and produce plastic injection parts for sampling and bulk production.We also provide mold design services.

Q: How can I contact you?

A: You can send us an inquiry via email, WhatsApp, Skype or Wechat. We will reply to you within 24 hours.

Q: How can I get a quotation?

A:After receving your RFQ, we will reply to you within 2 hours. In your RFQ, please provide the following information and data in order for us to send you competitive pricing based on your requirements.a) 2D part drawings in PDF or JPG format & 3D part drawings in UG, PRO/E, SOLIDWORKS, CATIA, CAD, STP, X_T, IGS, PRT, DWG, or DXFb) Resin information (Datasheet)c) Annual quantity requirement for parts

Q: What shall we do if we don’t have part drawings?

A: You can send us your plastic part samples or photos with dimensions and we could provide you our technical solutions. We will create .

Q: Can we get some samples before mass production?

A: Yes, we will send you samples for confirmation before start of mass production.

Q: Due to time difference with China and overseas, how can I get information about my order progress?

A: Every week we send weekly production progress report with digital pictures and videos that shows the production progress.

Q: What is your leadtime?

A: Our standard leadtime for mold production is 4 weeks.For plastic parts is 15-20 days depending on the quantity.

Q: What is your payment term?

A: 50% as payment deposit, 50% balance will be paid before shipping. For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred

Q: How can I guarantee our quality?

A: During mold making, we do material and part inspection. During part production, we do 100% full quality inspection

before packaging and reject every parts that is not according to our quality standard or the quality approved by our client.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.