2021 High quality Motorcycle Helmet Mould - Motorcycle Scooter Mould – Aojie Mould

2021 High quality Motorcycle Helmet Mould - Motorcycle Scooter Mould – Aojie Mould Detail:

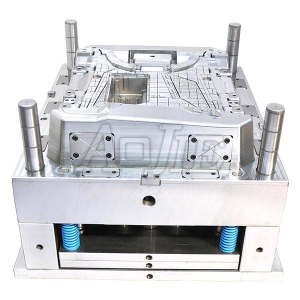

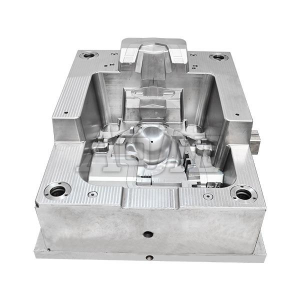

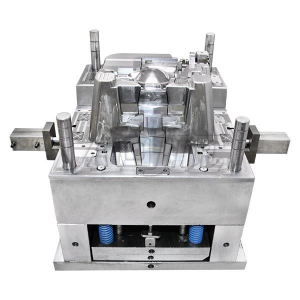

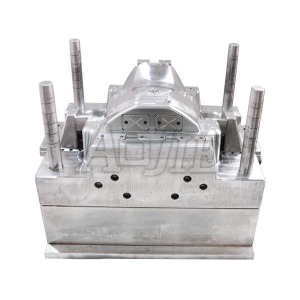

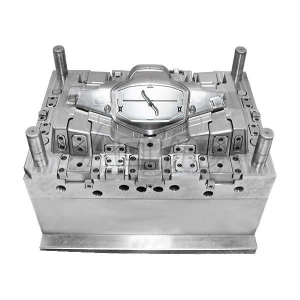

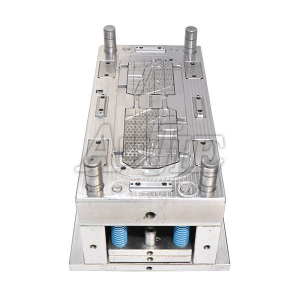

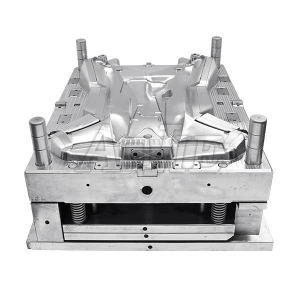

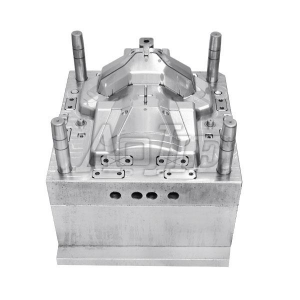

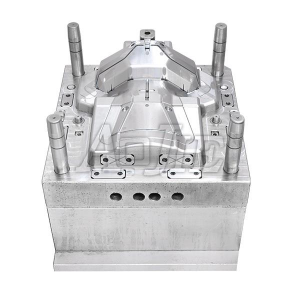

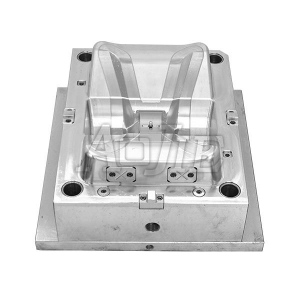

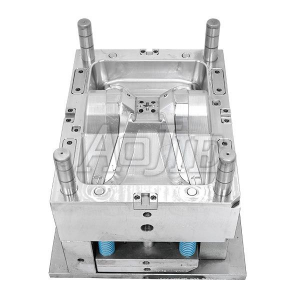

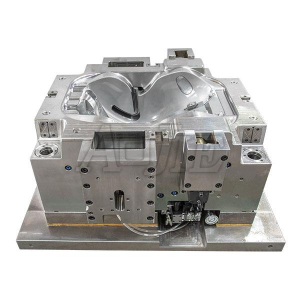

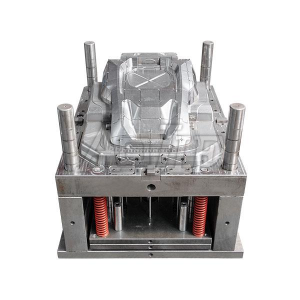

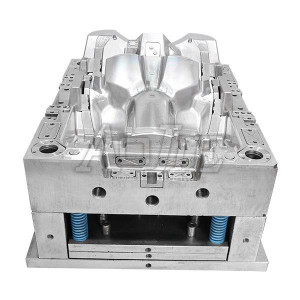

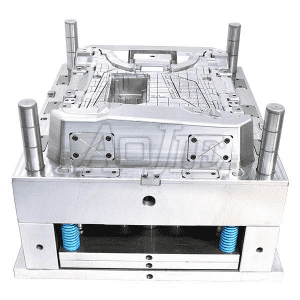

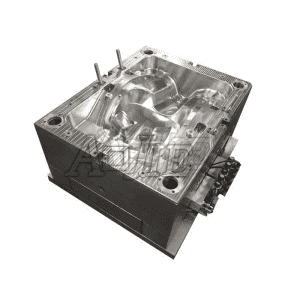

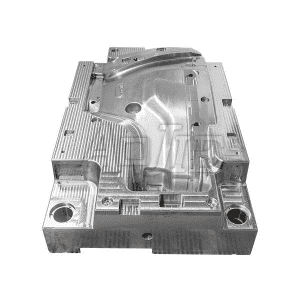

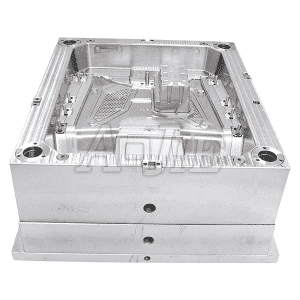

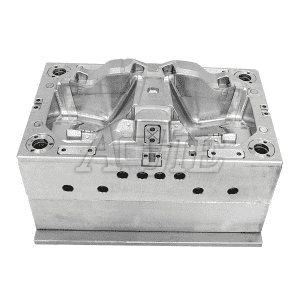

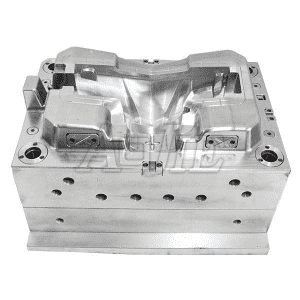

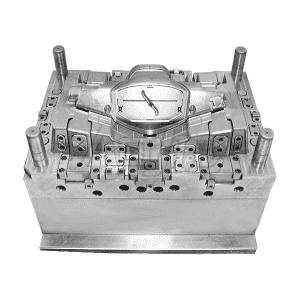

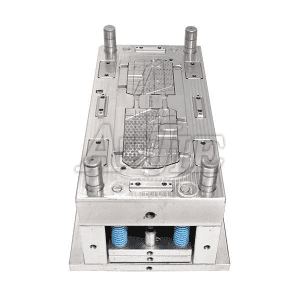

Motorcycle Scooter Mould

Product Name Taizhou Experienced OEM Motorbike rear cowl Plastic Mould

Product material abs

Core& Cavity Steel 718/2738

Steel hardness: HRC34-38

Mould Standard DME/LKM/HASCO

Cavity Number 1+1

Injection System side Gate

Ejector System ejector pin

Cycle Time 50seconds/shot

Tooling lead time 50days

Mould life 500, 000 times

Quality assurance ISO9001

Our Advantage

1. High quality

2. Reasonable price

3. On time delivery

4. Good After-sale service

5. Strict quality control

6. All the mould are automotic.

Offer you In-time response on letters, telephone calls or fax

In-time supply the quotation and mould designs

In-time communication on the technical points

In-time sending pictures for the mould machining progress and mould finishing schedule

In-time mould test and sample delivery

In-time mould delivery

Product detail pictures:

Related Product Guide:

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for 2021 High quality Motorcycle Helmet Mould - Motorcycle Scooter Mould – Aojie Mould , The product will supply to all over the world, such as: America, Sacramento, Benin, To have much more enterprise. ompanions, we've got updated the item list and seek for optimistic co-operation. Our web-site shows the latest and complete information and facts about our merchandise list and company. For further acknowledge, our consultant service group in Bulgaria will reply to all of the inquiries and complications immediately. They're about to make their finest effort to meet buyers need. Also we support the delivery of absolutely free samples. Business visits to our business in Bulgaria and factory are generally welcome for a win-win negotiation. Hope to expertise a happy company co-operation perform with you.

Q: What services do you provide?

A: We manufacture plastic injection molds and produce plastic injection parts for sampling and bulk production.We also provide mold design services.

Q: How can I contact you?

A: You can send us an inquiry via email, WhatsApp, Skype or Wechat. We will reply to you within 24 hours.

Q: How can I get a quotation?

A:After receving your RFQ, we will reply to you within 2 hours. In your RFQ, please provide the following information and data in order for us to send you competitive pricing based on your requirements.a) 2D part drawings in PDF or JPG format & 3D part drawings in UG, PRO/E, SOLIDWORKS, CATIA, CAD, STP, X_T, IGS, PRT, DWG, or DXFb) Resin information (Datasheet)c) Annual quantity requirement for parts

Q: What shall we do if we don’t have part drawings?

A: You can send us your plastic part samples or photos with dimensions and we could provide you our technical solutions. We will create .

Q: Can we get some samples before mass production?

A: Yes, we will send you samples for confirmation before start of mass production.

Q: Due to time difference with China and overseas, how can I get information about my order progress?

A: Every week we send weekly production progress report with digital pictures and videos that shows the production progress.

Q: What is your leadtime?

A: Our standard leadtime for mold production is 4 weeks.For plastic parts is 15-20 days depending on the quantity.

Q: What is your payment term?

A: 50% as payment deposit, 50% balance will be paid before shipping. For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred

Q: How can I guarantee our quality?

A: During mold making, we do material and part inspection. During part production, we do 100% full quality inspection

before packaging and reject every parts that is not according to our quality standard or the quality approved by our client.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.